The Impact of Deep Learning on Modern Manufacturing Processes

Introduction to Deep Learning in Manufacturing

The manufacturing industry has experienced a significant transformation with the advent of deep learning technologies. This subset of artificial intelligence (AI) has revolutionized how manufacturers approach complex problems, streamline processes, and increase efficiencies. By leveraging deep learning, manufacturers are now able to automate tasks that were once considered too intricate for machines.

Deep learning models, particularly neural networks, enable machines to mimic the human brain's ability to learn from data. These models are capable of identifying patterns and making decisions with minimal human intervention. The impact of this technology on modern manufacturing processes is profound, offering new opportunities for innovation and growth.

Enhancing Quality Control

One of the most significant impacts of deep learning in manufacturing is in the area of quality control. Traditional quality control methods often rely on human inspection and can be prone to errors and inconsistencies. Deep learning algorithms, however, can analyze images of products with high precision, identifying defects that might be missed by the human eye.

By implementing deep learning-based quality control systems, manufacturers can significantly reduce waste and improve product consistency. These systems can be trained to recognize even the most subtle deviations from set standards, ensuring that only products meeting high-quality benchmarks reach consumers.

Optimizing Production Efficiency

Deep learning also plays a critical role in optimizing production efficiency. Predictive maintenance, powered by AI, allows manufacturers to anticipate equipment failures before they occur. By analyzing data from sensors and other IoT devices, deep learning models can predict when a machine is likely to fail, allowing for timely maintenance and reducing downtime.

Moreover, deep learning can enhance supply chain management by predicting demand trends and optimizing inventory levels. This ensures that manufacturers maintain optimal stock levels, reducing both overproduction and stockouts.

Improving Robotics and Automation

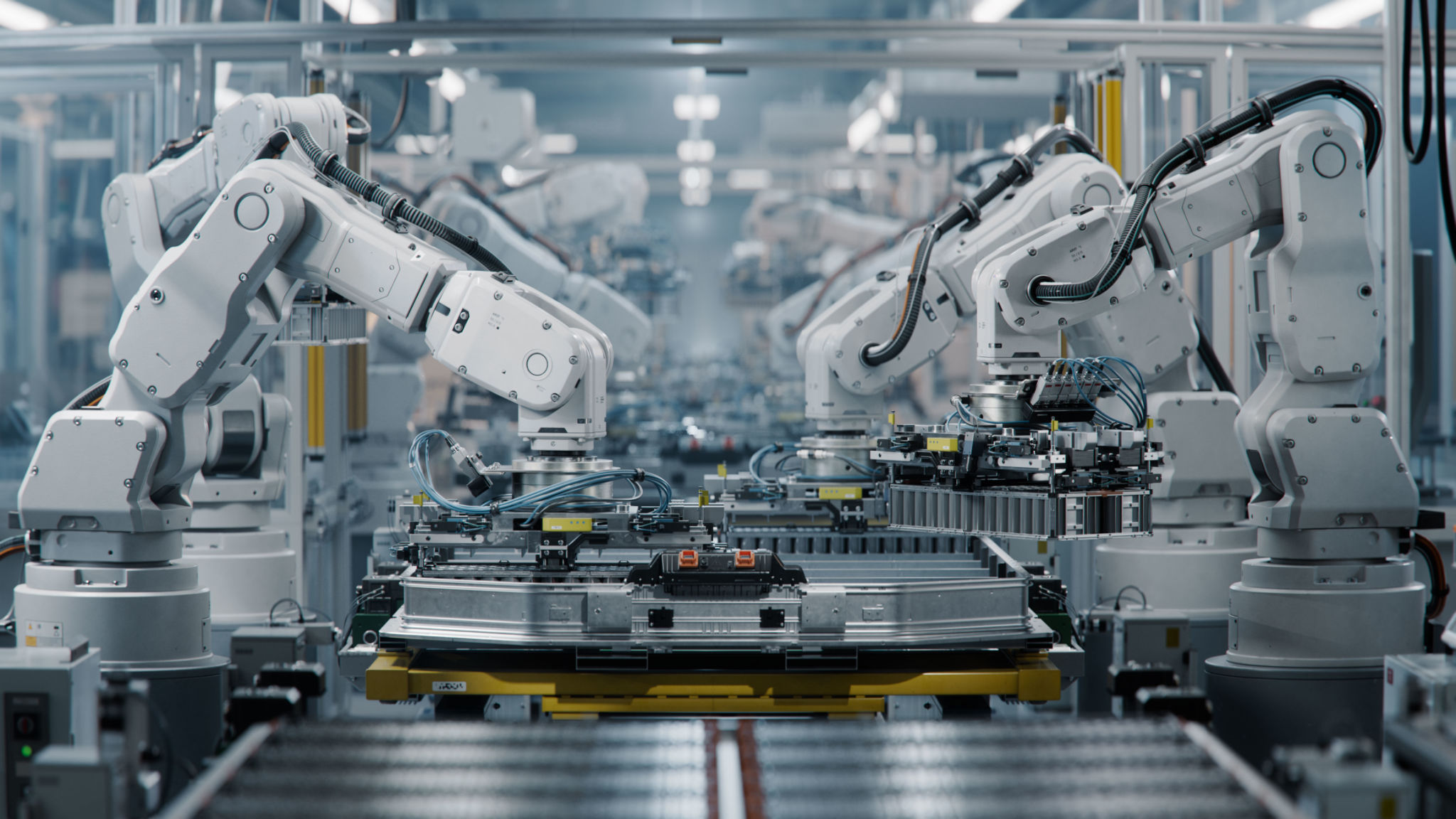

Robotics and automation have been integral to manufacturing for decades, but deep learning takes these technologies to new heights. Robots equipped with deep learning capabilities can perform complex tasks with greater accuracy and adaptability. This includes everything from assembling intricate components to handling delicate materials.

Deep learning enables robots to learn from their environment and improve their performance over time. This adaptability is crucial in industries where precision and flexibility are paramount, such as electronics and automotive manufacturing.

Addressing Challenges and Future Prospects

Despite its benefits, integrating deep learning into manufacturing processes presents challenges. High initial costs, data privacy concerns, and the need for specialized expertise are barriers that some manufacturers face. However, as technology advances and becomes more accessible, these challenges are gradually diminishing.

Looking ahead, the potential for deep learning in manufacturing is immense. As more companies embrace this technology, we can expect even more innovative applications and improvements in efficiency and productivity. The ongoing evolution of deep learning will undoubtedly continue to shape the future of manufacturing.